Our Products

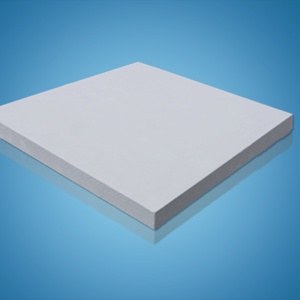

Nano microporous insulation board is a plate-like inorganic insulation material with very low thermal conductivity and good processing characteristics, especially suitable for applications with high requirements for energy conservation and environmental protection, especially in high-temperature applications where the thickness or weight of the insulation material is limited. This material has advanced technology, high economic benefits, excellent flame retardancy, and meets the industry standard of “A level” fire resistance rating.

Available in various sizes and specifications: length and width can be freely selected within a certain range, with a thickness of 1 to 50 millimeters, and multiple models are available for selection

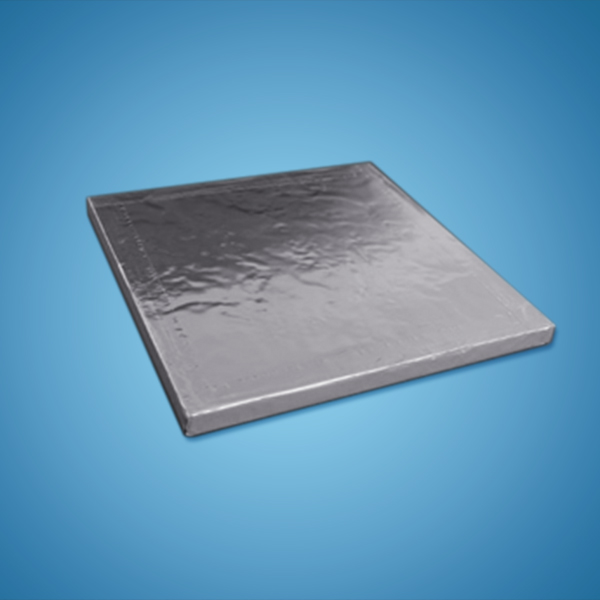

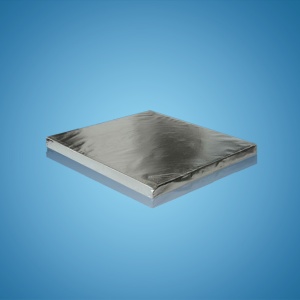

Rich external packaging forms: Customers can choose nano microporous insulation boards without packaging, or choose different packaging materials according to actual application needs. By selecting wrapping materials, the strength of the nanoboard can be enhanced, dust during installation can be reduced, and certain waterproof functions can be achieved. Optional wrapping methods: PE shrink film, aluminum foil wrapping, aluminum foil bonding, fiberglass cloth wrapping, composite with mica sheets, etc.

Mold customization: Customizing molds enables customers to accurately obtain the required product dimensions, thereby minimizing cutting waste. For large orders, customized molds have significant economic benefits for customers.

Typical application scenarios of nano microporous insulation boards include roller kilns, tunnel kilns, lithium electric kilns, aluminum electrolysis tanks, aluminum melting and insulation furnaces, glass kilns, incinerators, well furnaces, heat treatment furnaces, cracking furnaces, lifeboats, electric furnaces, etc.

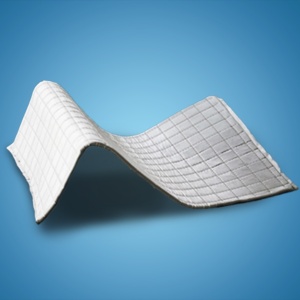

Nano Microporous Plate-VIP

Nano microporous plate VIP board is a highly efficient insulation material that combines microporous technology and vacuum technology by vacuum encapsulating the microporous insulation core material mainly made of fumed silica into a high resistance diaphragm bag. The material has a very low thermal conductivity (typical value: 0.004 W/m K), good cold insulation effect, long service life, and usually can reach over 50 years. The plate surface and plate edge are flat, which can reduce the heat leakage at the edge as much as possible. It is easy to install and transport, and has excellent anti-aging function. Even when the vacuum is lost, this material still has excellent thermal insulation performance, and has a very low expansion rate. The gas-phase silica core board uses environmentally friendly materials, which can be recycled and reused, ensuring safety and environmental protection.