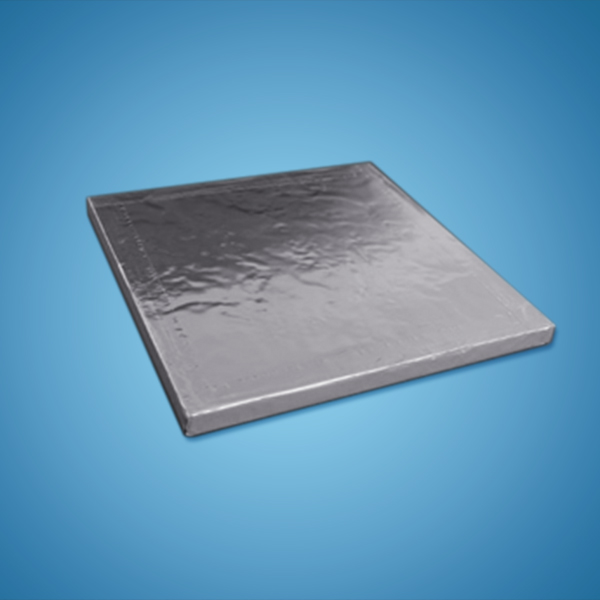

Nano Microporous Plate-Aluminum Foil

Product Description:

Anchor-Tech’s Microporous Plate-Aluminum Foil is a high-performance microporous insulation board made by laminating an aluminum foil layer onto the standard microporous board. The product is sealed with a dense protective layer, providing excellent waterproof, moisture-resistant, and dustproof properties, effectively resisting harsh environmental conditions.

The addition of the aluminum foil significantly enhances product performance. With outstanding radiant heat reflection, the foil greatly reduces the thermal conductivity of the microporous insulation board, boosting its insulation effect. Although aluminum foil can burn above 500°C, this does not affect the thermal insulation performance when the product is used as a back-layer insulation board.

Compared to the standard microporous board, Microporous Plate-Aluminum Foil maintains extremely low thermal conductivity. In practical applications, it achieves the same insulation performance as traditional materials with only one-fourth to one-sixth of the thickness. This makes it an ideal solution for space-constrained or thickness-limited insulation applications. The product is available with a classification temperature of up to 1200°C to meet various high-temperature requirements.

Microporous Plate-Aluminum Foil also offers excellent workability. It supports operations such as drilling, grooving, and cutting, allowing for easy customization on-site. Factory pre-cut and pre-shaped customization is also available upon request, further improving installation efficiency.

This product is especially suitable for applications with strict energy-saving and environmental requirements. Its dense structure minimizes dust emission and reduces the risk of dust inhalation for workers. In high-temperature industries such as automotive, household appliances, PV annealing furnaces, and sapphire sintering furnaces—where insulation thickness and weight are critical—Microporous Plate-Aluminum Foil offers unique advantages. With advanced production technology, outstanding cost-effectiveness, and excellent fire resistance, it has become a preferred choice across many industries. Thickness can be customized from 5 mm to 50 mm to meet diverse user needs.

Thermal Conductivity (W/m·K) – YB/T 4130-2005

200℃ | 0.021 |

400℃ | 0.023 |

600℃ | 0.027 |

800℃ | 0.034 |

Specifications:

Size(mm): | 500×600;1000×600 |

Thickness(mm): | 5~50 |

Operating temperature(℃) | 900,1100,1200 |

Density: (kg/m3), | 200~320, customizable |

Product Advantage

1. Excellent Structural and Protective Properties

Surface laminated with aluminum foil and sealed to form a dense protective layer

Outstanding waterproof, moisture-proof, and dustproof performance, ideal for harsh environments

Dense structure minimizes dust dispersion, reducing health risks for workers during installation

2. Superior Thermal Insulation Performance

Extremely low thermal conductivity, offering 3–4 times better insulation than traditional materials

Significantly reduces equipment energy consumption

Requires only 1/4 to 1/6 the thickness of conventional insulation to achieve the same performance

Effectively blocks infrared radiation for enhanced thermal shielding

3. Outstanding High-Temperature Resistance

Withstands continuous temperatures up to 1100°C

Available with a maximum classification temperature of 1200°C, suitable for various high-temperature environments

Although the aluminum foil may burn above 500°C, it does not affect the overall insulation performance when used as a backing layer

4. Excellent Workability and Machinability

Supports a wide range of processing options including cutting, drilling, and grooving

Can be easily worked with standard woodworking tools

Custom thicknesses (5–50mm), shapes, and dimensions available upon request

Simplifies on-site installation and enhances construction efficiency

5. Safe and Environmentally Friendly Material

Non-toxic, odorless, and smoke-free during heating

Contains no harmful respirable fibers; non-irritating to skin—suitable for household appliances

Non-powdering with a long service life, reducing maintenance needs

6. Excellent Fire Resistance

Classified as a non-combustible (Class A) material, ideal for fire-resistant insulation layers

Suitable for environments with strict fire protection requirements

7. Wide Range of Applications

Especially suited for installations with limited space or strict weight constraints

Ideal for use in automotive industry, household appliances, photovoltaic annealing furnaces, sapphire sintering furnaces, and more

Typical Application

Energy and Chemicals:

- Cracking furnace

- Hydrogen converter

- Distillation unit

- Fuel cell system

- SOEC

- TES

- CSP storage equipment

- Aluminum electrolytic cell

- Aluminum melting furnace

- Holding furnace

- Forging furnace

- Heating furnace

- Thermal barrier

- Roller hearth kiln

- Tunnel kiln

- Tempering furnace

- Annealing furnace

- Feeder

- Heat treatment furnace

- Pit furnace

- Electric heater

- Lifesaving capsule