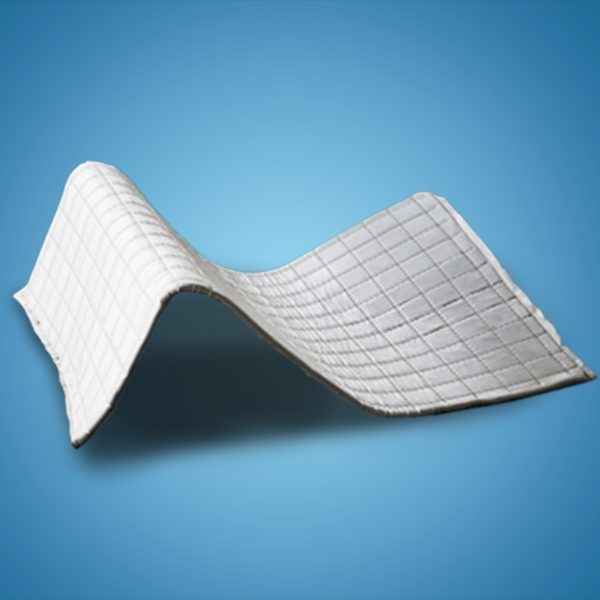

Nano Microporous Plate-Flexible

Product Description:

Anchor-Tech’s Nano Microporous Plate-Flexible is a flexible nano-microporous insulation sheet, specially designed for high-temperature equipment or pipelines with limited space. The material is fully customizable, including thickness, size, and fabric type. It supports both single-sided and double-sided stitching to meet different application needs.

The core is made of a nano-microporous structure with extremely low thermal conductivity—only 0.028 W/m·K at 600°C. Its insulation performance is several times better than traditional materials. It achieves the same thermal insulation effect using only 1/4 to 1/6 of the thickness, significantly saving installation space.

The product features a flexible design, wrapped in high-temperature-resistant fiberglass fabric and stitched for added durability. It offers excellent flexibility, allowing easy installation on curved surfaces and pipelines. The fiberglass outer layer is water- and dust-resistant, keeping the worksite clean, reducing airborne dust, and protecting installer health.

Nano Microporous Plate-Flexible is an ideal choice for improving energy efficiency and reducing heat loss. It is suitable for a wide range of industrial thermal insulation applications.

Thermal Conductivity (W/m·K), tested according to YB/T 4130-2005

200℃ | 0.021 |

400℃ | 0.025 |

600℃ | 0.028 |

800℃ | 0.034 |

Specifications:

Size(mm): | 1000*600,customizable |

Thickness(mm): | 5,10,customizable |

Operating temperature(℃) | 900,1100,1200 |

Density: (kg/m3), | 275, customizable |

Product advantages:

- Superior Thermal Insulation Performance: The core material adopts a nano – microporous structure with an extremely low thermal conductivity. At 600°C, it is only 0.028 W/m·K. The thermal insulation performance is 3 to 4 times that of traditional materials, which can greatly reduce the energy consumption of equipment and the required thickness of the insulation layer. Only 1/4 to 1/6 of the thickness of traditional materials is needed to achieve the same thermal insulation effect, effectively saving space.

- Excellent Flexibility and Adaptability: The product features a flexible design, with a high – temperature – resistant glass fiber cloth on the outside and is processed by sewing. It can be easily bent to fit various curved surfaces and pipelines. It is specially designed for equipment or pipelines in high – temperature environments and with limited space, showing strong adaptability.

- Good Protection Performance: The outer layer of the glass fiber cloth has waterproof and dustproof functions, which can keep the construction site clean, reduce the dispersion of dust, and protect the health of installation personnel.

- High Customization: The material can be customized in terms of thickness, size, and fabric type according to requirements. It supports single – directional or bidirectional sewing, meeting diverse application scenarios.

- Outstanding Thermal Properties: It has a small specific heat, low heat storage, and resistance to thermal shock. It can withstand temperatures up to 1100 degrees Celsius and can effectively block infrared radiation, ensuring stable thermal insulation performance in high – temperature environments.

- Long Service Life: The product will not be pulverized and has a long service life, allowing for stable long – term use and reducing replacement costs and frequencies.

- Green, Environmentally Friendly and Safe: It is non – toxic and environmentally friendly, contains no inhalable harmful fibers, is smokeless and odorless when heated, and does not cause itching when in contact with the skin. It can be applied to household appliances. At the same time, it is a non – combustible material and can be used as a fireproof thermal insulation layer, ensuring safe and reliable use.

- Convenient Processing: It can be processed by using woodworking tools such as cutting and drilling, which is convenient for installation and later adjustments, improving construction efficiency.

Typical Application:

- Cracking furnace

- Electronic instrument

- fire-proof door

- Aerospace equipment

- High temperature pipeline

- Steam pipeline

- Chemical pipeline

- heating furnace