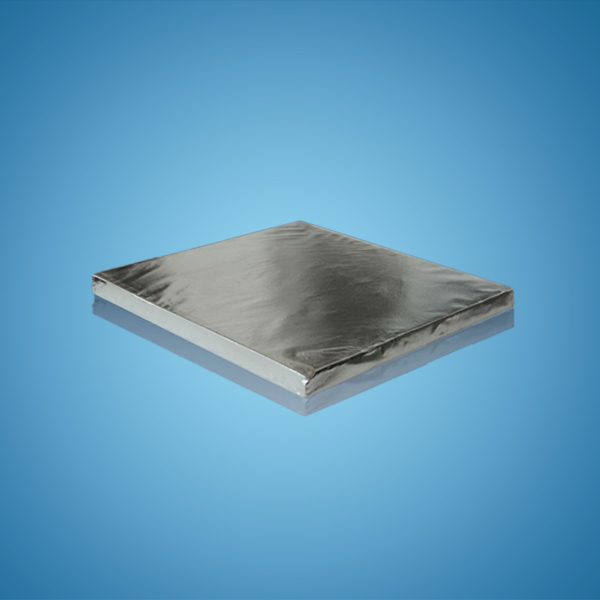

Nano Microporous Plate-VIP

Product Description:

Nano microporous plate VIP board is a highly efficient insulation material that combines microporous technology and vacuum technology by vacuum encapsulating the microporous insulation core material mainly made of fumed silica into a high resistance diaphragm bag. The material has a very low thermal conductivity (typical value: 0.004 W/m K), good cold insulation effect, long service life, and usually can reach over 50 years. The plate surface and plate edge are flat, which can reduce the heat leakage at the edge as much as possible. It is easy to install and transport, and has excellent anti-aging function. Even when the vacuum is lost, this material still has excellent thermal insulation performance, and has a very low expansion rate. The gas-phase silica core board uses environmentally friendly materials, which can be recycled and reused, ensuring safety and environmental protection.

Product advantages:

- VIP gas silicon vacuum insulation board adopts self-produced high-performance microporous core material, which has advantages such as good insulation performance, long service life, energy conservation and efficiency, and effective reduction of carbon emissions

- Very low thermal conductivity, which can be as low as 1/10 of traditional insulation materials.

- Long service life, up to 50 years or more.

- Even without vacuum, it has excellent insulation performance, superior to most other materials.

- Cold chain transportation and storage time are longer, ensuring the performance of the goods.

- Lightweight, can achieve compact structural design and reduce transportation costs.

- The expansion rate is very low during vacuum loss, and it is stable and long-lasting to use.

- Excellent compressive performance, not easily deformed.

- Can provide customized formulas, sizes, and processing shapes.

- No harmful inhalable fibers, safe and environmentally friendly.

Typical Application :

- Temperature controlled packaging – biomedical cold box, various Cooler

- Zero energy building or passive low energy building

- Heating or heat storage equipment (water heaters, boilers, and heat storage tanks)

- Household appliances (refrigerators, refrigerated storage cabinets)

- Refrigerated trucks, cold chain containers, etc

Product specification: | |

core material | Vapor-phase silica microporous insulation board |

measure | Length and width: maximum 950x1100mm, thickness: 5-50mm, customized as required. |

Application temperature | -70°C – +90°C |

density | 170-240 kg/m (other densities can be customized) |

Thermal conductivity | ≤4.0 mW/(m.K)@10℃ initial value |

VIP internal pressure | ≤5mbar |

compressive strength | 120 kpa (10% deformation) |

service life | Usually it can last for more than 50 years, depending on the actual application. |